The painting of a Mercian frame is not a quick process usually taking around 4 weeks to complete

The frame is primed with etch coat primer, which is allowed to air dry in the clean conditions of the finishing room before being carefully rubbed down with fine grade paper to give a first class base for the paint.

We use the finest quality stove enamel paints we can obtain, these are also kinder to the Sprayers and the environment than two pack paints. Stove enamel paints must be baked in an oven to give the finest long-lasting finish possible.

Most of our 63 colours are not straight out of the tin, but are mixed by hand by our sprayers resulting in the rich, deep, vibrant shades that we offer. We can mix colours in enamel or pearl paints to match a sample if required, we have had been asked to match clothing colours, old school ties and car colours, we’re lucky to have sprayers that are very experienced and conscientious who use their skill to give your frame the look you want, it will only leave the workshop when the sprayer is happy with the final finish.

Contrasting head tube and seat tube panels, also Barbers Poles are sprayed then baked before being masked up and rubbed down with fine grade paper to give the coats of the main finish a good base. The main colour is sprayed and the masking is removed carefully while the paint is still wet, a tricky job as you might appreciate, before baking at the optimum temperature to ensure that the finish is not only long lasting and durable, but looks amazing.

FLAMBOYANT COLOURS

Flamboyant paints are translucent coloured paints sprayed in a number of coats over a silver or gold base coat. There is no pearl in the flamboyant paint itself, the sparkle and light reflections come from the base coat which shines through the flamboyant top coat in daylight.

POLYCHROMATIC COLOURS

Polychromatic paints are ‘flatter’ metallic paints, they are metallic but no pearl/flake. A lovely bright metallic paint for those who don’t want too much sparkle.

ENAMEL COLOURS

Enamel paints are deep gloss paints, no sparkle in the paint, but a vibrant rich colour with a wide choice of colour options.

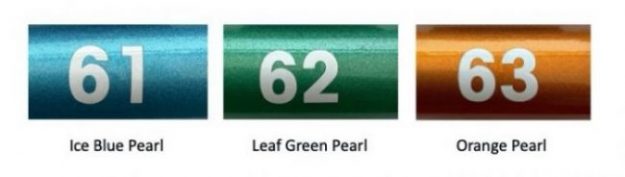

PEARL COLOURS

Pearl paints have a small metallic flake in the paint, not at all garish but a subtle sparkle in the paint itself giving depth and reflection, a fabulous looking paint in the sunshine.

COLOUR CHART PDF FOR DOWNLOAD

Lugs are lined by hand. This is a very skilled and time consuming job that takes months to perfect even with daily practice. The frame finisher gets the right consistency of paint and with a steady hand, follow the contours of the lug to neaten any area where two paint colours meet or to pick out the lugs to show them off to their full potential.

Transfer fitting is another skilled role needing a steady hand and dextrous touch when dealing with the application of tissue-thin transfers. Transfers are fitted and left to air dry for up to 5 days before varnishing. We use a combination of varnish-fix transfers or dry-fix transfers to give the best finished look possible to the frames, many coats of varnish add the final gloss and protection to all the paintwork and transfers before a final stoving in the oven completes the painting process.

Before leaving the workshop, the threads and the inside of the seat tube are cleaned of any excess paint or varnish to get the frame ready for the components.

Finally the frame is checked over prior to despatch for for building into a complete cycle.

COLOUR CHART